Case overview

The project aims to develop a real-time production monitoring system and periodic historical analysis. The system will be able to collect data from various sources, including sensors, machines, and control systems, and process it to provide useful information to operators and production managers.

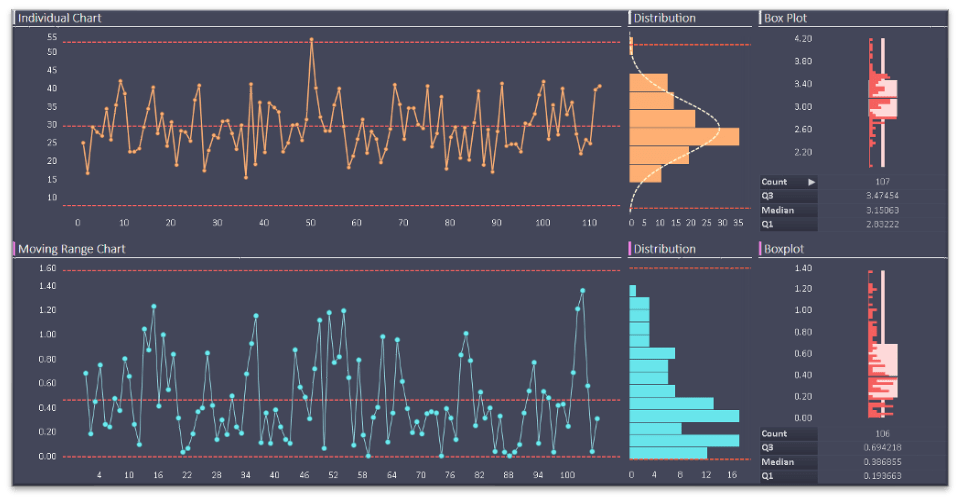

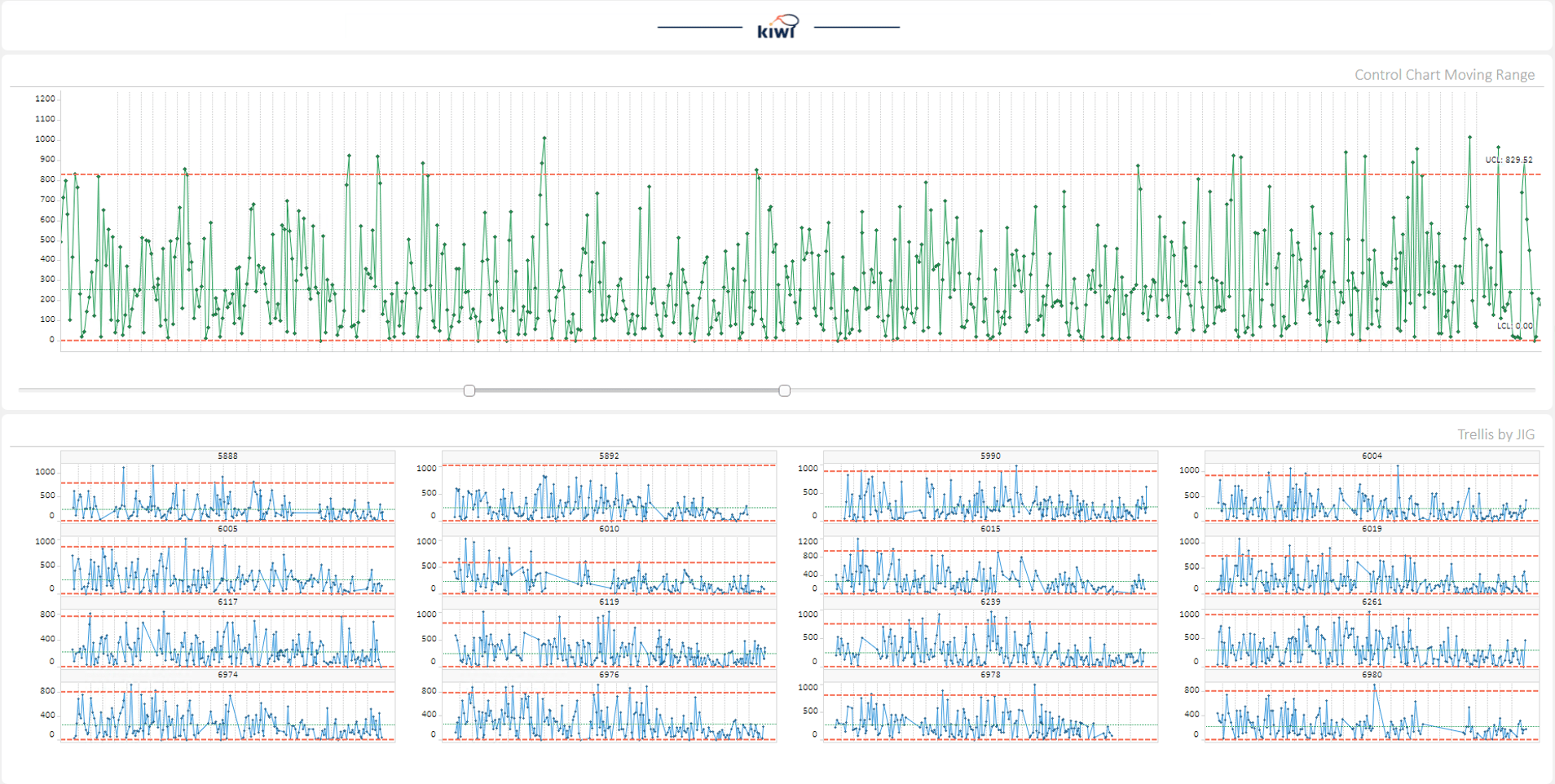

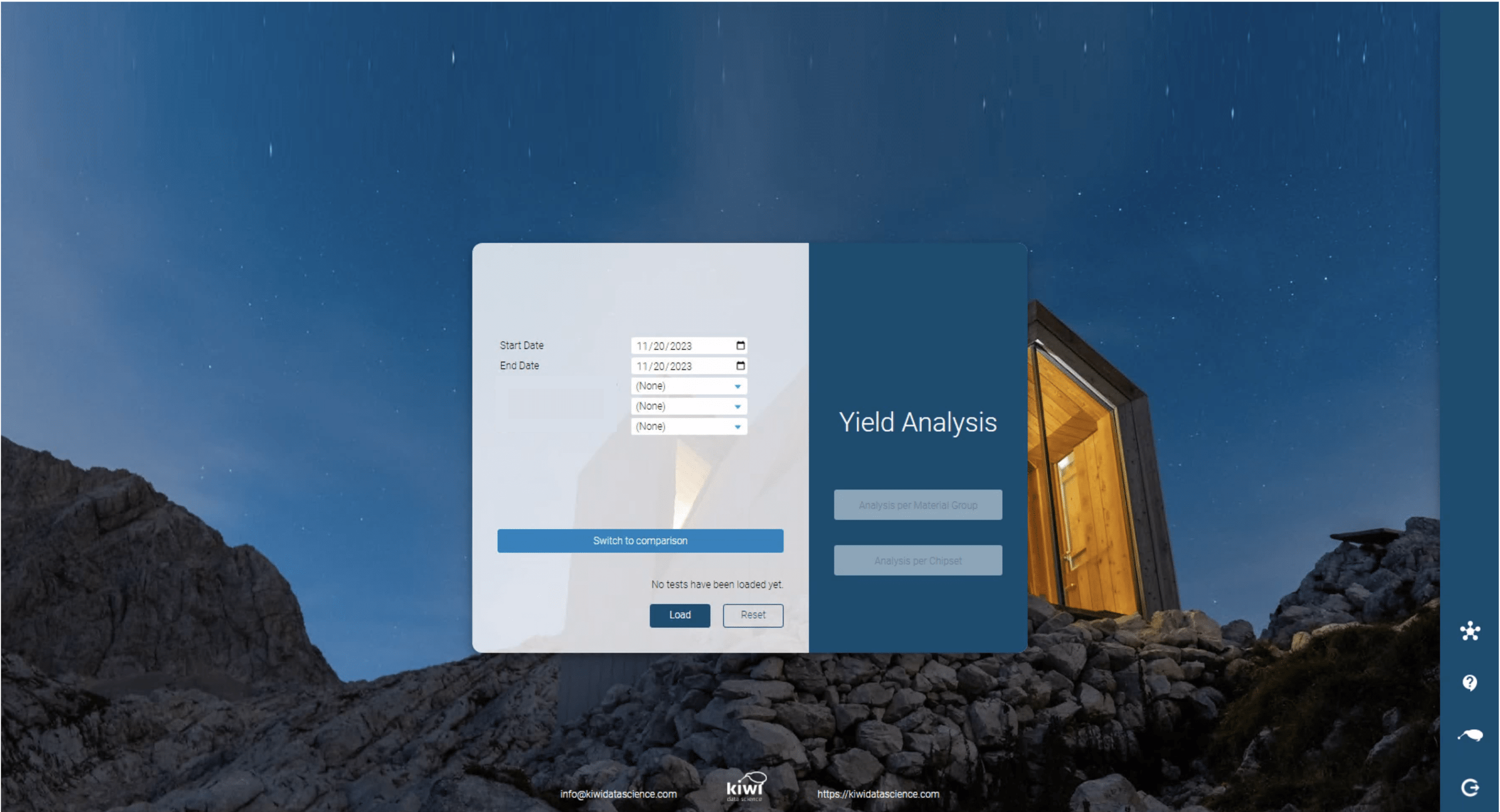

Yield Monitoring

One of the analyses that will be performed by the system will be the monitoring of the production yield value. Production yield is an indicator that measures the amount of finished product produced relative to the amount of raw material used. In the project, production yield will be monitored in real time. This will allow for the rapid identification of any problems and intervention to resolve them.

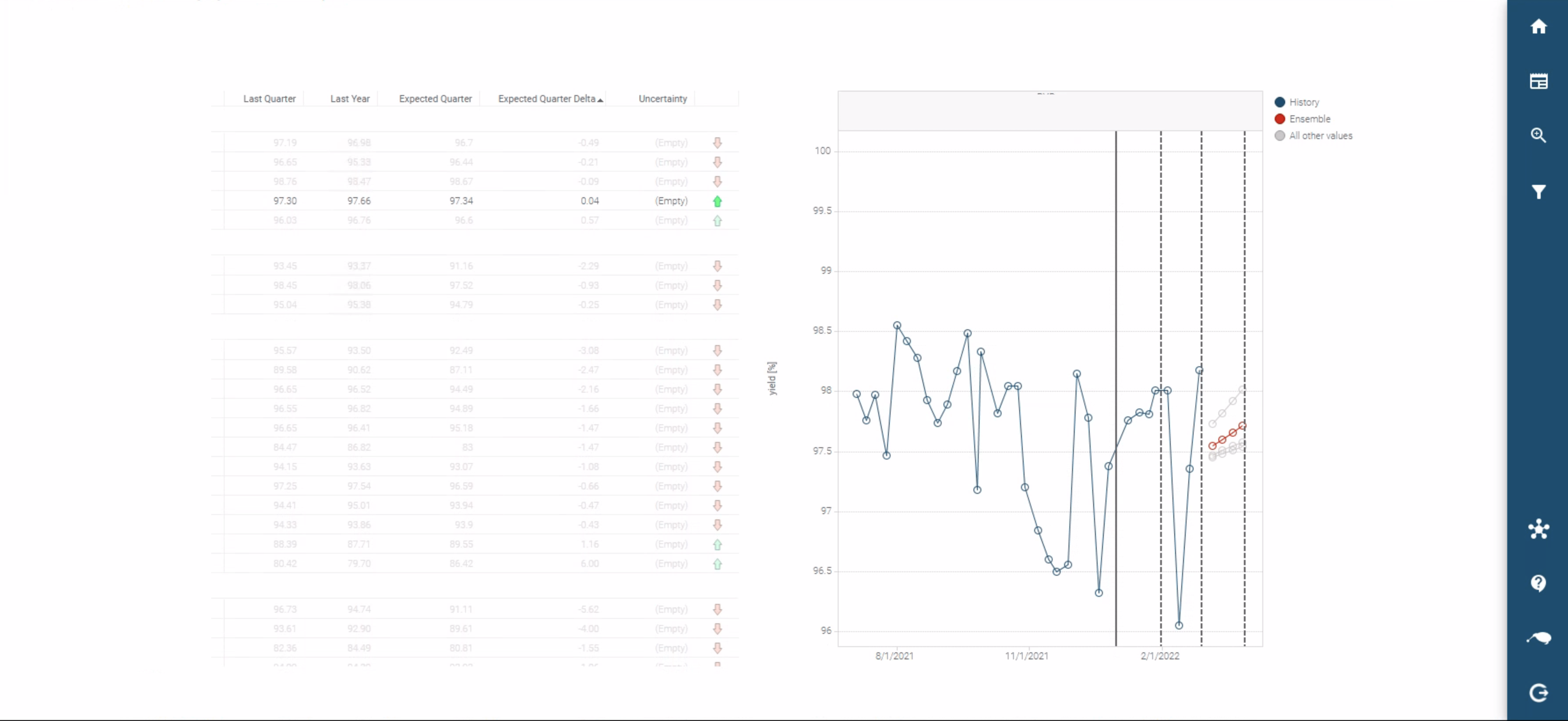

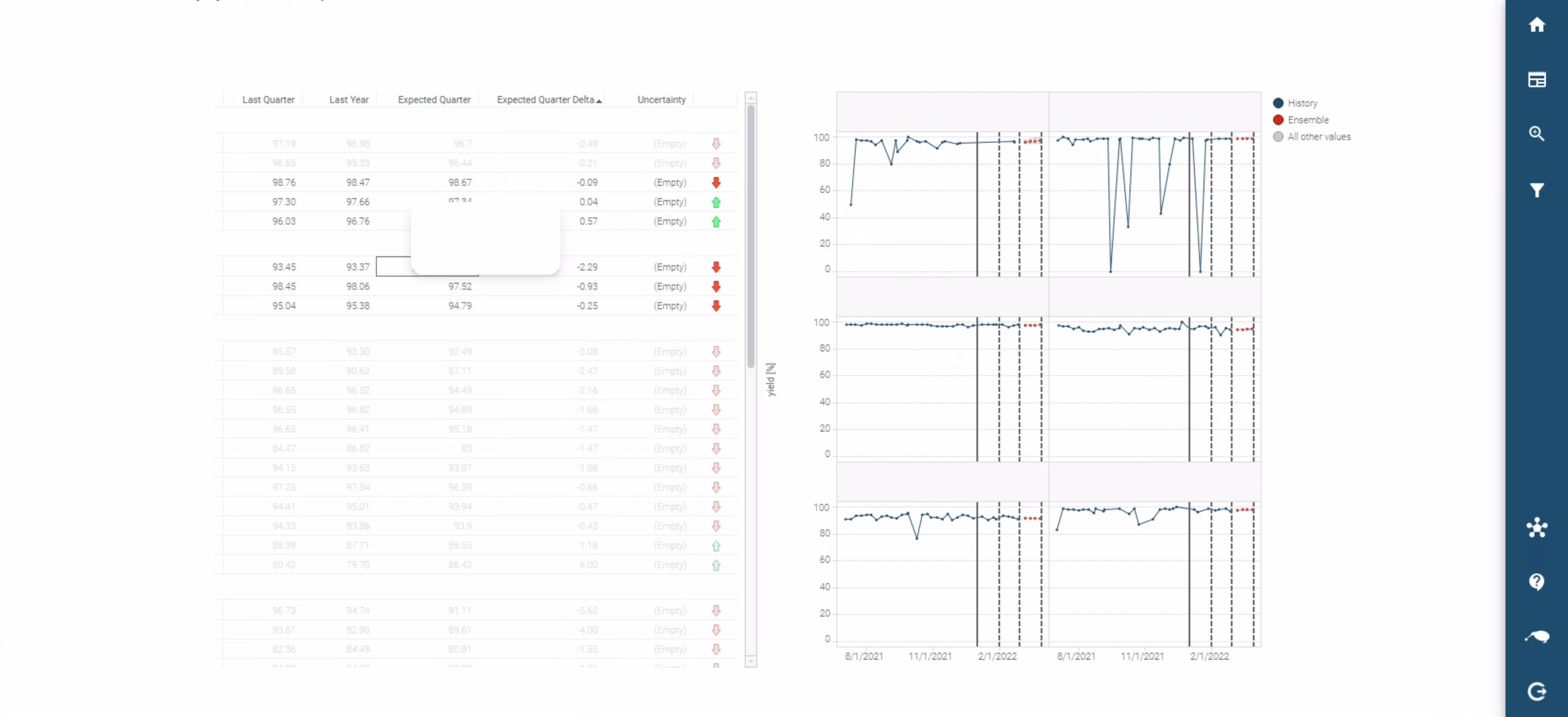

Yield Forecast

In addition to the aforementioned analyses, the system also tackled the task of predicting the current quarter’s yield. Employing machine learning models proved instrumental in this endeavor, paving the way for more efficient production planning. This yield prediction capability was achieved by training machine learning models on historical production data.

The Results

In conclusion, the idea to develop a real-time production monitoring system and periodic historical analysis has yielded significant benefits for the company. In the next year, the project has improved production efficiency, reduced production costs, improved product quality, increased workplace safety, and improved production planning and optimization. These benefits have had a positive impact on the company’s bottom line and its overall reputation.